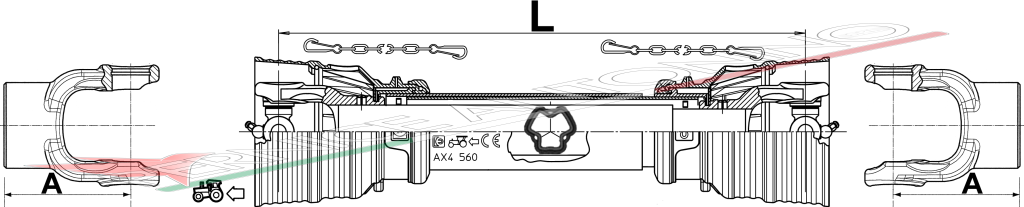

PTO drive shaft without outside yokes

PTO drive shaft without outside yokesArt. PE031964

€ 1,112.80

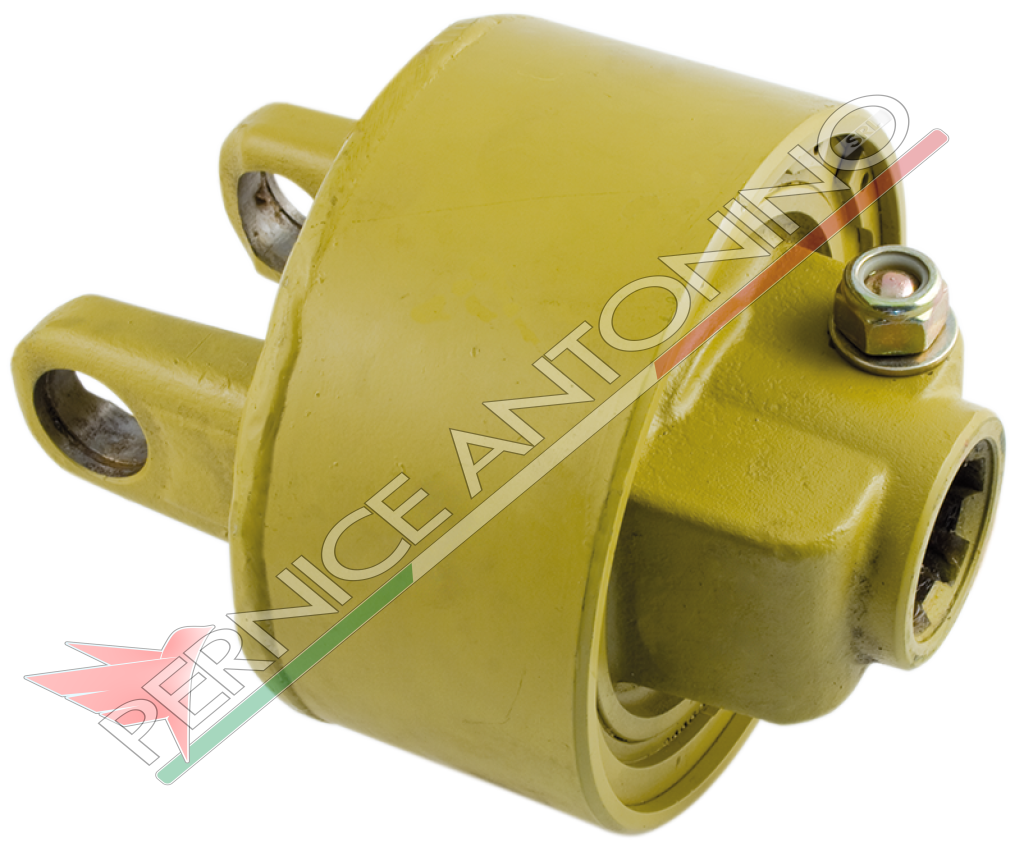

Torque limiter with automatic reset

Category12 Profile1"3/4 - Z.6

Data

Maximum torque4500 Nm

Cross47.6x135 mm

PTO shaft category12

Profile1"3/4 - Z.6

Length - A226 mm

Diameter - B- mm

net weight17 kg

Spare parts for

PTO drive shaft without outside yokes

PTO drive shaft without outside yokesFamily description: MECHANICALLY DISENGAGED TORQUE LIMITER WITH AUTOMATIC RESET…Application: The LDR torque limiter is recommended in cases where, following an overload, an immediate interruption of the torque and therefore an immediate stop of the driven machine is required, in order to avoid breakage of the transmission or of the machine itself. The state of intervention is perceptible by hearing the typical intermittent noise that the device emits during the disconnection state or by noting the inactivity of the driven machine.

Maintenance: The LDR can be disassembled and reassembled without the need for special tools as the cams are not under the spring tension when the device is engaged. The particular construction reduces, also depending on use, the need for maintenance that can be performed by lubricating the device from the outside.

Features and operation: The LDR torque limiter is of the radial cam type, acting in a single direction of rotation (also available in the version with opposite rotation), which ensures the transmission of torque up to the preset calibration value by means of a spring. conical of the Belleville type. At the time of intervention, the LDR limiter disconnects the power transmission, canceling the transmitted torque unless there is a residual pulsating torque, necessary for subsequent restoration. Reset occurs automatically when the transmission rpm is reduced to a minimum value sufficient for the purpose and function of the device calibration (on average 250 rpm).

The value of the calibration torque is preset in the factory and can be changed by the user after appropriate replacement of the spring. Thanks to the residual pulsating torque reduced to a minimum, overheating and vibrations during the intervention are also reduced to a minimum.

Compact dimensions, reduced weight, use of plain bearings and the use of quality materials allow the device to be used even for speeds of over 1000 rpm. Locking system with conical clamp or interfering bolt. Special executions on request.

Maintenance: The LDR can be disassembled and reassembled without the need for special tools as the cams are not under the spring tension when the device is engaged. The particular construction reduces, also depending on use, the need for maintenance that can be performed by lubricating the device from the outside.

Features and operation: The LDR torque limiter is of the radial cam type, acting in a single direction of rotation (also available in the version with opposite rotation), which ensures the transmission of torque up to the preset calibration value by means of a spring. conical of the Belleville type. At the time of intervention, the LDR limiter disconnects the power transmission, canceling the transmitted torque unless there is a residual pulsating torque, necessary for subsequent restoration. Reset occurs automatically when the transmission rpm is reduced to a minimum value sufficient for the purpose and function of the device calibration (on average 250 rpm).

The value of the calibration torque is preset in the factory and can be changed by the user after appropriate replacement of the spring. Thanks to the residual pulsating torque reduced to a minimum, overheating and vibrations during the intervention are also reduced to a minimum.

Compact dimensions, reduced weight, use of plain bearings and the use of quality materials allow the device to be used even for speeds of over 1000 rpm. Locking system with conical clamp or interfering bolt. Special executions on request.